WHITE PAPER

Reducing TAT in Aviation MRO: Best Practices in Component Induction and Asset TrackingAugust 2025

Key Takeaways:

- Reducing Turnaround Time (TAT): Learn how modern digital MRO solutions like Impresa streamline component induction and asset tracking to cut TAT by up to one-third.

- Real-Time Visibility and Automation: See how real-time inventory tracking, predictive analytics, and automated workflows improve operational readiness and compliance.

- Best Practices for Efficiency: Explore actionable strategies such as barcode/RFID scanning, predictive analytics, and digital thread alignment to enhance maintenance processes.

EXECUTIVE SUMMARY

Optimizing Aviation MRO Operations with Real-Time Data and Digital Integration

In the fast-paced world of aerospace and defense MRO management, reducing aircraft turnaround time (TAT) is essential to operational readiness, cost control, and mission success. Maintenance planners, schedulers, and technical operations leaders face growing pressure to streamline processes, integrate data across MRO systems, and maintain compliance, all while managing increasingly complex fleets and components.

This white paper explores how modern digital MRO software solutions, such as Impresa™ MRO software, empower organizations to significantly reduce TAT by improving component induction and MRO asset tracking. Backed by real-time data and intuitive workflow tools, Impresa offers aerospace and defense leaders a scalable MRO platform and a proven path to operational excellence.

5X INCREASE IN CAPACITY

400% INCREASED THROUGHPUT

28% IMPROVEMENT OF ON-TIME DELIVERY

1/3 REDUCTION IN TURN-AROUND TIME

Industry Context: The Challenge of TAT in Complex MRO Environments

According to Oliver Wyman’s 2024 MRO Survey, global maintenance demand continues to rise sharply, driven by fleet growth and aging platforms. At the same time, the Teal Group notes increasing strain on MRO capacity, especially in military aviation, where mission-readiness is non-negotiable. One of the most persistent bottlenecks is component induction, MRO traceability, and asset tracking.

Without digitized workflows and integrated MRO systems, key stakeholders struggle with:

- Incomplete or delayed component histories

- Manual entry errors during part induction

- Lack of real-time MRO inventory visibility

- Difficulty complying with FAA, EASA, or DoD tracking standards

The Impresa Advantage: Streamlining MRO Induction & Asset Tracking

Advanced MRO Asset Management

Impresa™ MRO software provides powerful aircraft MRO software and MRO management capabilities that enable users to track serialized components, subassemblies, tools, and equipment throughout their entire lifecycle, from acquisition to decommissioning. This level of granularity ensures complete traceability, which is critical for maintaining FAA, EASA, and DoD audit readiness. Each asset is assigned to a unique identifier, which can be linked to barcode or RFID tags, significantly accelerating component induction and reducing the risk of manual entry errors.

By capturing detailed asset history and usage patterns, maintenance teams can improve their Mean Time to Repair (MTTR), and plan service activities based on real-time operational data. This also supports more accurate maintenance forecasting, ensuring resources and parts are allocated proactively, not reactively. The result is improved uptime, reduced compliance risk, and better lifecycle management of mission-critical components.

Smart Component Induction Workflows in Aviation MRO

Impresa MRO software provides powerful MRO asset management capabilities that enable users to track serialized components, subassemblies, tools, and equipment throughout their entire lifecycle—from acquisition to decommissioning. This level of granularity ensures complete MRO traceability, which is critical for maintaining FAA, EASA, and DoD audit readiness. Each asset is assigned to a unique identifier, which can be linked to barcode or RFID tags, significantly accelerating induction and reducing the risk of manual entry errors. By capturing detailed MRO inventory history and usage patterns, maintenance teams can improve their Mean Time to Repair (MTTR), and plan service activities based on real-time operational data. This also supports more accurate maintenance forecasting, ensuring resources and parts are allocated proactively, not reactively. The result is improved uptime, reduced compliance risk, and better lifecycle management of mission-critical aviation components.

Real-Time MRO Inventory and Location Awareness

Impresa’s integrated MRO inventory management system gives planners, schedulers, and technicians complete visibility into the real-time status of parts, tools, and consumables. From warehouse to workbench, every component’s location, quantity, and usage history is tracked and accessible in a centralized aircraft MRO software platform. This level of insight helps avoid unnecessary part orders, delays caused by misplaced inventory, or unexpected shortages. Teams can implement just-in-time (JIT) stocking strategies for frequently used repair kits, improving cost control and reducing inventory carrying costs. Furthermore, Impresa supports intelligent reorder thresholds that adapt to actual usage trends and manages primary to alternate part relationships, helping avoid overstocking while maintaining operational readiness. These capabilities replace siloed spreadsheets and tribal knowledge with a system-driven MRO solution, significantly accelerating induction and repair timelines while enhancing supply chain agility.

Work Order Integration and MRO Analytics

One of the most powerful aspects of the Impresa MRO software solution is its ability to link asset management data, component induction workflows, and real-time MRO work order management into a single, cohesive workflow. As parts and assets are inducted into the MRO platform, they are immediately associated with active or scheduled work orders, ensuring continuity and visibility throughout the aircraft maintenance cycle.

Technicians and supervisors can view real-time updates on repair status, labor hours logged, MRO inventory consumed and required inspections. This real-time feedback loop enhances decision-making and enables tighter scheduling and resource planning. Impresa also includes robust MRO analytics tools and dashboards that provide insight into key performance indicators (KPIs) such as turnaround time, rework frequency, root cause trends, and technician efficiency.

With this data, operations leaders can benchmark performance, identify bottlenecks, and implement continuous improvements across aviation MRO sites, ultimately accelerating fleet readiness and lowering cost per maintenance event.

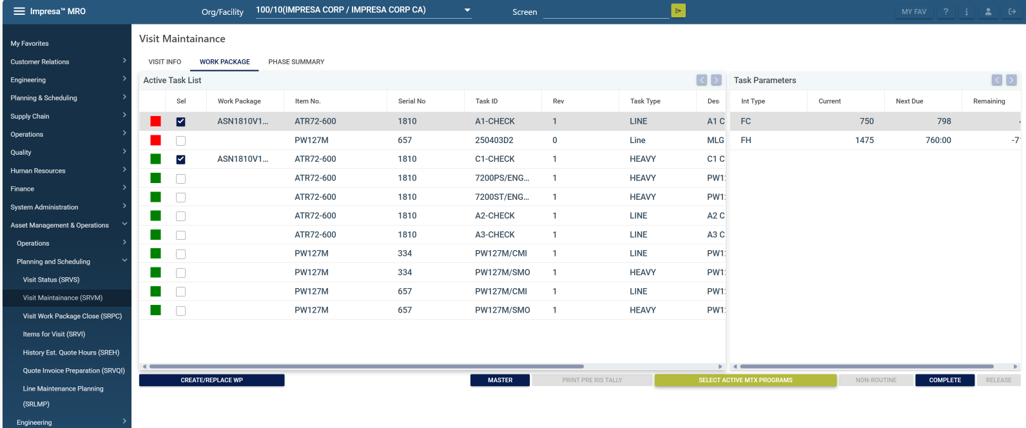

Impresa™ MRO software interface showing integrated work order management, real-time asset tracking, and analytics dashboards that enhance decision-making and accelerate TAT.

Manage Non-Routine (Unplanned) MRO Work

One of the key reasons for increased aircraft TAT in aviation MRO operations is the discovery during initial inspection of issues needing repair that was not part of the plan. These unexpected findings cause significant changes to the planned MRO work scope. The repair instructions for the unplanned work must be approved along with the plan for repair, requiring additional labor, parts, and tools.

Impresa MRO software simplifies the non-routine process by using historical MRO maintenance data based on the defect code (DC) and the corresponding cause and corrective action (CCA) thereby helping reduce the MRO TAT significantly.

Best Practices for Reducing Aircraft MRO Turnaround Time

Based on industry research (Frost & Sullivan, STS Aviation Group) and customer feedback, Impresa recommends these MRO best practices for reducing TAT and improving efficiency across aircraft MRO software platforms and operations:

| Best Practice | Benefit |

| Implement barcode/RFID scanning | Speeds up induction and reduces manual errors |

| Standardize component intake forms | Minimizes variability and improves compliance |

| Use predictive analytics | Identifies parts likely to fail before arrival |

| Automate asset routing and tracking | Accelerates inspection and disposition decisions |

| Aligns with digital thread strategy | Enables full traceability across lifecycle |

Why Choose Impresa MRO Software

Impresa self-hosted, end-to-end MRO software is purpose-built for mission-critical aerospace and defense operations. Unlike generic ERP or point solutions, Impresa delivers secure, scalable, and fully integrated MRO capabilities that unify people, parts, tools, files, and data into a single platform, giving organizations complete control over their infrastructure and information.

Key Differentiators:

- Enterprise-class MRO platform capabilities without enterprise cost

- Customizable workflows for highly regulated aviation MRO environments

- Data-driven decision-making through integrated MRO analytics

- Trusted by global aerospace and defense MRO leaders to maintain operational readiness

Conclusion: Orchestrating Aviation MRO Excellence

Reducing MRO turnaround time requires more than isolated tools, it demands orchestrating the five critical assets of aviation maintenance: people, parts, tools, files, and data. Impresa is the self-hosted, end-to-end MRO platform that acts as the conductor, bringing these assets into harmony and transforming operational chaos into a coordinated performance.

By unifying asset management, inventory visibility, and real-time analytics, Impresa empowers aerospace and defense teams to streamline workflows, maintain compliance, and maximize fleet availability. The result is improved efficiency, reduced risk, and a sustainable path to mission readiness.

References

Oliver Wyman. (2024). *Global Fleet & MRO Forecast 2024–2034*. Oliver Wyman Aerospace, Defense & Government Services. Retrieved from https://www.oliverwyman.com

Teal Group Corporation. (2024). *Aerospace & Defense Market Analysis*. Retrieved from https://www.tealgroup.com

Frost & Sullivan. (2024). *Strategic Outlook on Global MRO & Aftermarket Services*. Aerospace & Defense Practice. Retrieved from https://www.frost.com

STS Aviation Group. (2024). *MRO Industry Trends & Best Practices*. Retrieved from https://www.stsaviationgroup.com

Aviation Week Network. (2024). *MRO Americas Reports and Surveys*. Aviation Week Intelligence Network (AWIN). Retrieved from https://aviationweek.com

Federal Aviation Administration (FAA). (2024). *Compliance and Certification Handbook*. Retrieved from https://www.faa.gov

U.S. Department of Defense. (2024). *Maintenance and Readiness Directives (DoD 5000.97)*. Retrieved from https://www.esd.whs.mil/DD

© 2025 Impresa Corp. All rights reserved.

This whitepaper and its contents are the intellectual property of Impresa Corp. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means—electronic mechanical, photocopying, recording, or otherwise—without the prior written permission of the publisher, except in the case of brief quotations used in critical reviews or scholarly works.

Impresa Corp. retains all rights to the methodologies, case studies, and concepts presented herein. For permissions or licensing inquiries, please contact info@impresa-us.com

Disclaimer: The information provided in this whitepaper is for general informational purposes only. While every effort has been made to ensure the accuracy and completeness of the content, Impresa Corp. makes no warranties, express or implied, and assumes no legal liability for the use of this information. Readers are encouraged to seek professional guidance specific to their operational or regulatory requirements.