WHITE PAPER

The Paperless MRO Blueprint: How Aviation Maintenance Organizations Can Digitize FAR-145 WorkflowsNovember 2025

Key Takeaways:

- Eliminate up to 75 paper documents per LRU overhaul with fully digital FAR-145 workflows

- Accelerate compliance with FAA-accepted e-signatures and electronic recordkeeping

- Achieve instant, searchable access to maintenance records using OCR-ready digital documentation

- Reduce operational delays by enabling Anywhere / Anytime / Any Device access across the maintenance environment

- Unlock seamless audit readiness with complete traceability across all electronic work packages

EXECUTIVE SUMMARY

The Paperless MRO Blueprint

The Paperless MRO Blueprint outlines How Aviation Maintenance Organizations Can Digitize FAR-145 Workflows and eliminate the inefficiencies of paper-based processes. This whitepaper explains the regulatory requirements for electronic signatures and digital recordkeeping, highlights the operational costs of traditional paperwork, and presents a clear roadmap for transitioning to electronic work packages, searchable documents, and fully digital maintenance records.

Readers will learn how modern MRO/ERP systems improve compliance, reduce turnaround time, strengthen audit readiness, and support “Anywhere, Anytime, Any Device” access across the maintenance environment. This blueprint gives MRO leaders a practical guide to accelerating digital transformation and building a more efficient, compliant, and sustainable operation.

Why Paperless Aviation Maintenance Is Now Essential

By paperless aviation maintenance we specifically mean the transition from traditional paper-based systems and maintenance documentation to fully digital solutions that supports the shop floor, engineering quality, supply chain and customer services operations. This shift improves efficiency, enhances safety, reduces environmental impact, reduces errors and aligns with modern regulatory frameworks.

What are the key strategies and requirements for implementing paperless aviation in commercial component maintenance companies?

Digital transformation underpins Accessibility and Electronic Documents – A powerful triangle.

The aviation industry understands the urgent need to reduce its carbon footprint. With a paper-based system a single LRU going through a repair shop under overhaul would generate paper for each one of the following FAR-145 standard process steps.

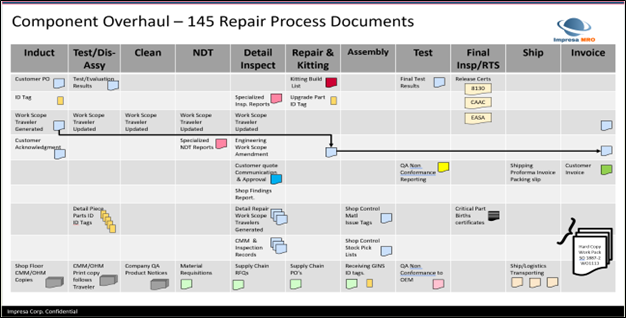

Figure 1

A conservative estimate shows that of one LRU Assembly overhaul might generate somewhere between 50 to 75 separate bits of paper all of which are necessary to document compliance to OEM maintenance instructions. At the end of the process all these documents are stored in a box and held in an offsite storage facility for a minimum of 2 years. Computerized copies of maintenance records have been around for some time now but while these offer easier access opportunities and cost savings, rigorous demonstration is required to ensure that unaltered maintenance documents relating to any air incident can be retrieved for NTSB scrutiny.

With approximately 3500 USA based maintenance repair shops that services 4000 to 6000 customer units per year, and Aircraft maintenance facility providing A, B, C and D type checks which have inspection and repair maintenance cards in the thousands for each as maintained aircraft, the paper generated for aircraft maintenance is extremely large, and its care financially burdensome.

A recent comment by a senior aviation vice president said:

“We wanted electronic records 10 years ago and we are just getting it now”.

Digital records, and their widespread use, and their electronic retention for regulatory scrutiny are long overdue.

What the Regulations Say

Advisory Circular AC_120_78B paragraph 1.9.2 basically outlines that:

“FAA acceptance is required for certificate holders to use electronic signatures, electronic recordkeeping systems, and electronic manual systems to satisfy the requirements of 14 CFR parts 91K, 121, 125, 133, 135, and 145. FAA acceptance is also required for certificate holders who use electronic records, and the electronic signatures associated with those records, to satisfy the requirements of 14 CFR parts 141, 142, and 147.”

It is important to note that the FAA does not require a certificate holder to use electronic signatures, electronic recordkeeping systems, or electronic manual systems, and that the AC is not enforcing the rule but providing guidance on a range of matters on electronic signatures, electronic record keeping, and electronic manual systems.

How an organization accomplishes paperless operations is up to them. Once satisfied that the MRO organization has met the guidance principles, the FAA will issue acceptance.

Electronic Maintenance Documents

The companies that have successfully completed the first phase of digitization take each completed work package and scan the documents creating pdf images of each page. Once completed the work package is reviewed ensuring that ID stamps and approval signatures are legible. Filing of these hard copy records moves the storage form paper in warehouses to electronic files in data centers specifically constructed to provide network connectivity services and direct internet access. Storage, conversion and accessibility are now big business.

One of the drawbacks to this type of digitization is once you scan a paper document into a PDF file, you may notice that you can’t search the text. Your scanner captures the pages as a flat image, which means there’s no text your PDF viewer can recognize. This can be a problem, especially with text-heavy documents.

Using OCR technology, the pdf file image can be converted to a searchable format. Once in this format the pdf files become searchable and open to interrogation by search tools and artificial intelligence applications.

Therefore, ensuring that all documents that are generated from MRO/ERP systems can be saved in readable/searchable format would reduce the OCR conversion effort.

If you are to be successful in a project of this type, all interactions with parts, engineering drawings, overhaul manuals and quality documentation, supply chain and customer communication, need to be carried out using a MRO/ERP application and third-party integrated systems.

The printing of pre-formatted reports and forms and manually writing information on to these documents and forms will not sit well with paperless organization strategies.

Accessibility

While electronic systems of record entered aviation maintenance in the last quarter of the 20th century, in aviation maintenance the wireless revolution didn’t get off the ground until 2010. By 2016 a limited 25% of aviation professionals had equipped their teams with wireless maintenance capabilities. Nine years on we still see spreadsheets, word document and PDF forms as part of the standard ordinance to combat interdepartmental communications, status reporting and production delays.

Like all companies watching their bottom lines, spending money on information technology has become a necessary evil instead of an opportunity. This is most prevalent when it comes to supporting application access and license counts.

For every new hire the IT Department must obtain new licenses. This is costly. Not only is a company required to spend scarce dollars to training new personnel, but they must buy system access licenses as well. With remote working, Wi-Fi technologies, low-code software tools, open API integrations and increasing numbers of B2B data exchange platforms, the MRO/ERP license model and its per month per user fee no longer serves the aerospace industry.

The MRO software providers and their VARS should review their licensing policies. It does no good to have aerospace maintenance companies going out of business. Remember that due to an aging and retiring workforce, the Aerospace industry in North America is projected to have a shortfall of 20,000 to 25,000 workers in 2025 alone.

The Aviation industry is not only going to have to fight to attract STEM educated personnel into the sector from a smaller candidate pool, but with the 1997 – 2020 generation, access to information via phone and PDA applications are standard. Books are not!

MRO/ERP providers should help rather than hinder. Letting companies grow without looking at the license count over their shoulders would be a huge start.

Access AW/AT/AD/EE – Anywhere, Any Time, Any Device/Every Employee

Digital Transformation for Maintenance

Where does one begin the program that will get us on to a path of paperless maintenance. There are about 8 basic steps to managing a program of this nature. For Owner operators the inclusion of electronic logbooks and electronic flight bags is a welcome addition to paperless organizations, but we will exclude them here since our focus is on MRO shops.

Paperless Aviation Transition Checklist

- Strategic Planning

- Define scope (fmaintenance, dispatch, etc.).

- Perform a gap analysis of current paper-based systems. (RIE project)

- Build a business case (ROI, compliance, safety).

- Appoint a digital transformation lead/project team.

- Develop a phased implementation roadmap.

- Regulatory & Compliance

- Identify applicable regulatory bodies (FAA, EASA, etc.).

- Engage early with the regulator for project approval.

- Prepare documentation for approval (Ops Manual updates, risk assessments).

- Establish policies for data retention and audit trails.

- Ensure conformance with e-signature regulations (eIDAS, ESIGN, etc.).

- Digital Manuals & Document Control

- Obtain digital operations maintenance manuals

- Use a document management system (DMS) with version control.

- Implement approval and update workflows.

- Make documents accessible offline in case of connectivity loss.

- Audit for readability, formatting, and update frequency.

- Cybersecurity & Data Integrity

- Conduct a cybersecurity risk assessment.

- Implement data encryption (at rest and in transit).

- Apply multi-factor authentication for sensitive systems.

- Set up regular backups and a disaster recovery plan.

- Monitor access logs and unauthorized access attempts.

- Training & Change Management

- Develop training programs for all roles (flight crew, engineers, dispatch, IT).

- Include procedures for digital tools and backup/failure handling.

- Provide quick-reference guides and eLearning modules.

- Collect feedback and improve training iteratively.

- Connectivity & Infrastructure

- Equip Facility with secure Wi-Fi (no dead zone)

- Upgrade IT systems for data hosting (cloud or hybrid).

- Test integration across departments (M&E, Shipping, Ops).

- Digital Signatures & Approvals

- Choose compliant e-signature solution (e.g., DocuSign, Adobe Sign).

- Ensure compatibility with company policies and regulations.

- Establish secure audit trails for all approvals and sign-offs.

- Monitoring, Feedback, and Continuous Improvement

- Monitor system usage and reliability metrics. Monitor the number of printers.

- Implement feedback loops (crew, maintenance, dispatch).

- Set review cycles for content accuracy and digital tool performance.

- Plan regular audits for compliance and improvements.

The digital revolution means “Any Where, any time, any device, every employee (AW/AT/AD/EE). To move toward this, we can create a punchout list (Part 1 Gap Analysis) of items and tasks, some examples of which are listed below:

General Requirements

Wi-Fi Networks – no dead zones

Semi-rugged notepads for all employees

Electronic CMM, OHM, RSM, QA Notices, etc. – (Electronic Revision Service)

Electronic document retention and retrieval

Access DAR Engineering Drawings and 3D models (Read Only Access)

CAD/CAM Programs (Revision Control) centralized

Backup & Disaster Recovery protocols

Electronic storage of MRO/ERP application user guides

MRO/ERP Capabilities Requirements

Approval codes and names for supporting documentation authorization

Reprint facilities for searchable PDF documents

Online Access to electronic maintenance manuals

Access to Engineering drawings & 3D models

Access to CAD/CAM Programs at the point of use

Access to MRO/ERP Online Help and Application User Guides

Controlled desktop data, image and file upload capability

E-recording of QA test results

E-recording of part defects and approved repair actions

E-recording of QA non-conformances

E-recording of Non-Routine Defect and corrective Actions

Electronic Generation of Regulatory Release Certification

Filing of PDF searchable formatted documentation

Online generation of Reliability reports

Online generation of Shop Findings reports

Online generation of Shop Travelers reports

Electronic sign off on traveler work orders with date & time stamp for all maintenance records

Online generation of Customer Quote reports

Online generation of Supply Chain RFQ, Requisition and PO reports

Online generation of Goods-in-Notes, Stocking and Issue tags

Required Printed Media That Is Generated From The MRO/ERP System

The regulations require that every physical part in a facility must have an ID tag and for the vast majority of MRO shops that means that there will be label and tag printing. Some examples are:

Shop Floor Customer Product ID Tags

Part Scrap Tags (visibly different from Serviceable tags)

Stock ID and Locations Labels

Warehouse and Bin Location Labels

WIP Shop Location Labels

Tooling Calibration Labels

Shop Machine Equipment Scheduled Plant Maintenance Tags

While this list isn’t exhaustive, starting a Rapid Improvement Event (RIE) project to identify all paper usage in the company will never go to waste. For confirmation of maintenance paper usage, the company Repair Station Manual is always a good start.

Not only will this exercise identify your gap analysis, but it will probably bring to light data silos and paper hand offs that fall into the category of “that’s they way we have always done it”.

Impresa MRO Paperless Maintenance – Are we there yet?

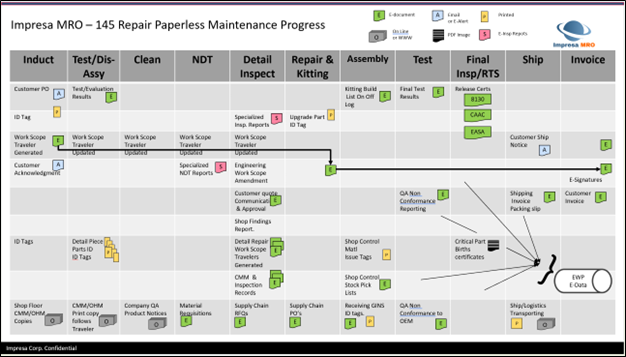

Comparing the overhaul and repair process in Figure 1 (paper forms for everything) to the current Impresa MRO electronic document capability, Figure 2, we see that apart from the printed media used for product identification and facility labeling, all of the documents that record and support maintenance are electronically generated and can be included in an electronic work package EWP that can be saved on a local secure storage area network with back up recovery options available within your own infrastructure or in an external secure cloud access storage.

Figure 2

Call to Action – Tree Huggers Unite!

There really is no opposition to moving to a paperless organization. A colleague recently noticed that one of the printers in the inspection shop floor area after only two years of operation had clocked up over 1.3M printouts. At $5 per ream (500 sheets of paper) the annual cost of printing just for the paper for this single printer was $6,500.

Where does your organization want to be next year? Is paperless operations one of your key objectives? Let Impresa Corp help you achieve this.

References:

https://www.faraim.org/faa/far/cfr/title-14/part-91/index.html#seqnum91.417

eIDAS or the Electronic Identification and Trust Services Regulation

© 2025 Impresa Corp. All rights reserved.

This whitepaper and its contents are the intellectual property of Impresa Corp. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means—electronic mechanical, photocopying, recording, or otherwise—without the prior written permission of the publisher, except in the case of brief quotations used in critical reviews or scholarly works.

Impresa Corp. retains all rights to the methodologies, case studies, and concepts presented herein. For permissions or licensing inquiries, please contact info@impresa-us.com

Disclaimer: The information provided in this whitepaper is for general informational purposes only. While every effort has been made to ensure the accuracy and completeness of the content, Impresa Corp. makes no warranties, express or implied, and assumes no legal liability for the use of this information. Readers are encouraged to seek professional guidance specific to their operational or regulatory requirements.