Self-Hosted MRO Software for Aviation Complexity

Impresa™ MRO unifies planning, execution, and compliance into one platform, reducing turnaround time (TAT), strengthening regulatory compliance, and giving providers full control over their systems and data.

Impresa MRO software is purpose-built for aviation, not adapted from ERP or PLM. Our self-hosted platform integrates inventory control, labor tracking, tool calibration, compliance, and work order management into a single system. From heavy maintenance and fleet modifications to component shops and line operations, Impresa delivers real-time visibility across the entire maintenance lifecycle. Aviation providers cut turnaround time, improve audit readiness, and lower operational costs with a proven aircraft maintenance software designed by aerospace professionals.

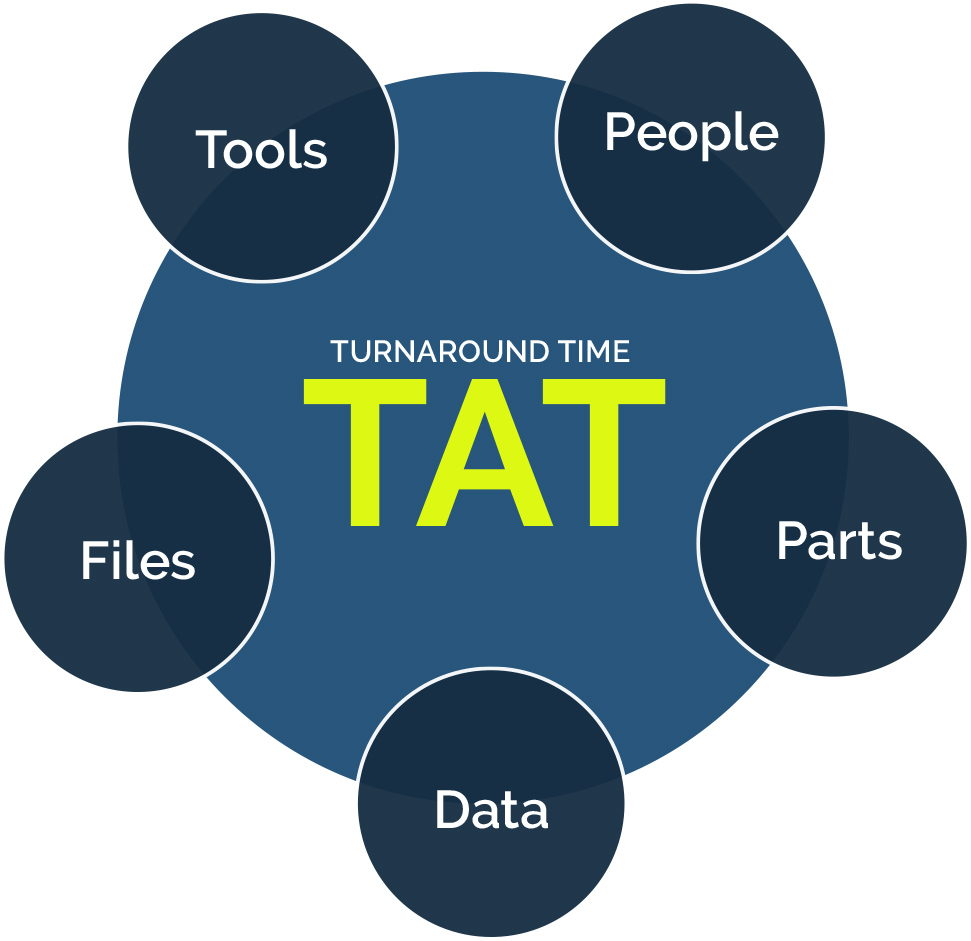

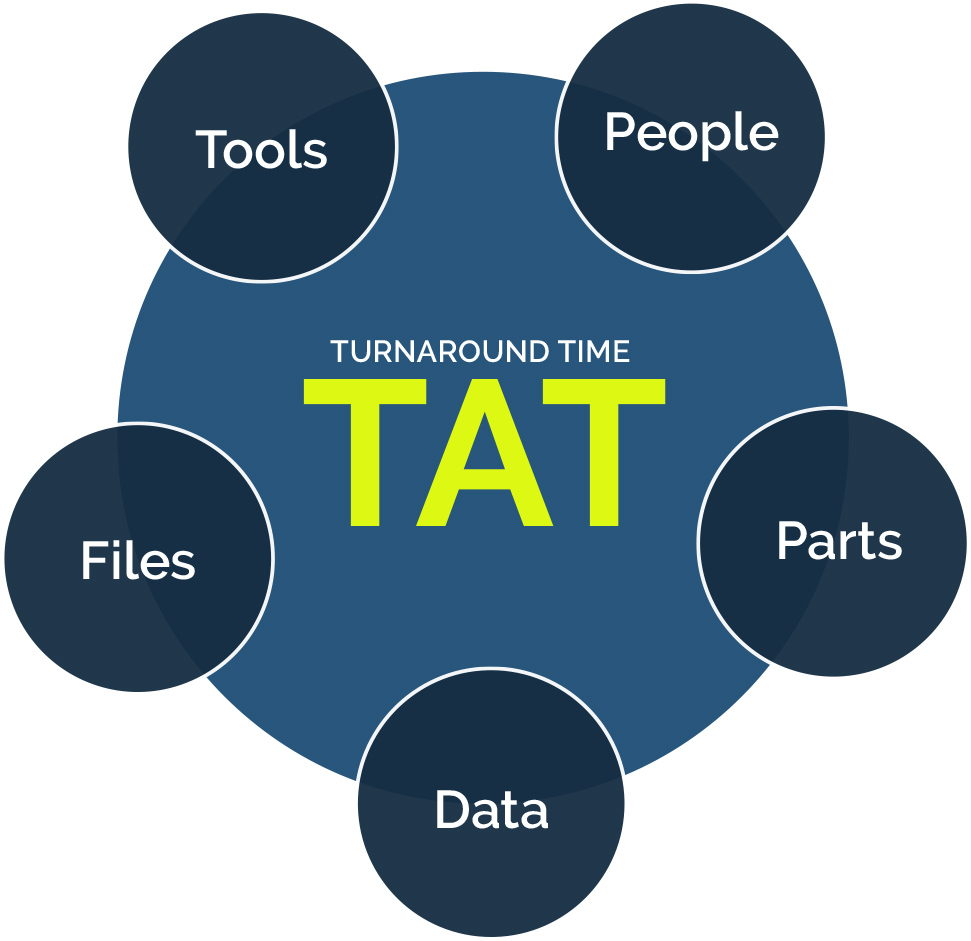

Success in aviation maintenance depends on synchronizing five critical assets into one connected MRO platform. Impresa MRO gives providers real-time visibility and control across people, parts, tools, files, and data—reducing TAT and ensuring compliance with regulatory standards.

Five Critical Assets Behind Every Aircraft Turnaround

Tools

Track tool readiness, calibration, and usage to prevent delays and ensure compliance.

Files & Documents

Task cards, work orders, manuals, service bulletins, controlled with version history and real-time updates.

Data

Power planning, scheduling, compliance checks, and analytics with accurate powered by real-time data.

People

Assign the right technician with the right certifications to the right task at the right time.

Parts

Gain end-to-end parts availability and traceability with barcode/RFID tracking and supplier visibility.

End-to-End MRO Software Across Every Function

From sales quote to close-out and compliance, Impresa MRO orchestrates every stage of the process with real-time visibility, efficient execution, and audit-ready records.

Base Enablers

of MRO

These are the systems, resources, and inputs that underpin all operations:

- Sales, Customer Contact and Quote Management

- Work Scope Management

- Supply Chain and Vendor/Supplier Contract Management

- Inventory Management

- Labor Controls

- Asset Management

Execution and

Process Control

These are the operational processes that transform drivers into coordinated action:

- Engineering

- Planning Management

- Execution Planning

- Compliance Management and Quality

- Finance

- MIS Management

Business

Impact

- Efficiency and Productivity Gains

- Regulatory Compliance and Risk Reduction

- Profitability and Growth

- Customer Satisfaction and Competitive Advantage

Synchronizing Every Asset for Faster Turnaround

Parallel Program Execution: Run multiple aircraft checks and heavy modifications at once with real-time oversight.

Parts Traceability: Assign technicians by role, skills, and certifications while tracking planned vs. actual performance.

Workforce Scheduling: Schedule technicians by role, skills, and certifications; monitor planned vs. actual.

Tool Management: Track thousands of tools with calibration status and location to prevent compliance delays.

Document Control: Manage task cards, work orders, and service bulletins with version history and audit-ready records.

By unifying these five critical assets in one self-hosted platform, Impresa reduces TAT, minimizes risk, and ensures every maintenance program runs efficiently.

Purpose-Built for Every Aviation MRO Environment

Impresa MRO adapts to the specific demands of every maintenance operation. Our platform synchronizes planning, automates task execution, and provides real-time visibility—delivering faster turnarounds, lower costs, and ensuring full compliance.

Heavy Modifications

Accelerate program speed with automated task sequencing, real-time progress dashboards, and digital sign-offs—purpose-built for serialized airframe and engine assets.

Line Maintenance

Enable rapid line operations with mobile access to task cards, live parts status, and airworthiness documentation at the point of service.

Heavy Maintenance

Improve planning accuracy and reduce costs with integrated workforce scheduling, material readiness, and package execution from a single system.

Component Maintenance

Increase shop throughput with modular workflows, serial and lot number traceability, and barcode/RFID inventory control that scales with your operation.

Other Capabilities

Impresa also supports parts sales, consignment, field service, rotables and exchanges, engineering services, asset disassembly, and power-by-the-hour programs.

Impresa MRO FAQs

What makes Impresa MRO different from other MRO software?

Impresa is aviation-first, not adapted from another industry. Designed by aerospace professionals, it reduces computer touch time, improves execution, and delivers:

- Two-minute induction for new customer orders.

- Instant shop load vs. capacity (no master scheduler).

- Out-of-the-box reports and dashboards.

- Open APIs for integrations and custom analytics.

- And much more

What types of MRO Operations does Impresa support?

- Heavy Modifications — automated sequencing, real-time progress, digital sign-offs for serialized assets.

- Heavy Maintenance — workforce scheduling, material readiness, check package execution in one dashboard.

- Component Maintenance — modular workflows, parts traceability, RFID/barcode inventory control.

- Line Maintenance — mobile task cards, parts availability, airworthiness documentation for rapid turnaround.

- Field Maintenance — connectivity anywhere, anytime, on any device for field crews.

- Part Sales — the business of selling aircraft components, parts, and materials used in the MRO of aircraft. This involves supplying airlines, maintenance providers, and other operators with the necessary parts to keep aircraft operational and airworthy.

- Consignment Sales — a supply chain model where an MRO provider (consignee) stores and manages spare parts and components owned by another company (consignor) at MRO’s location. The consignee only pays for the parts when they are used in maintenance or repair work, rather than upfront. This allows the MRO to access necessary parts quickly without the initial cost of purchasing them, while the consignor can reduce storage costs and potentially monetize surplus inventory.

- Rotables and Exchanges — a system of managing and maintaining aircraft components that are designed to be repaired and reused multiple times rather than replaced outright. Rotables are components like engines, landing gear, or avionics systems that can be economically and repeatedly restored to a serviceable condition after use. Exchanges involve swapping out a component for a repaired or overhauled one, minimizing downtime during maintenance.

- Asset Disassembly for Stock — commonly known as aircraft part-out or teardown, involves systematically dismantling end-of-life aircraft to salvage and reuse their still-serviceable components.

- Make-To-Order and Local Manufacture — represents distinct approaches to part production and sourcing. Both methods address specific needs within the MRO industry, driven by factors like customization requirements, supply chain resilience, and cost optimization.

- Field Service — MRO activities performed on aircraft, aircraft components, and related systems outside of a fixed maintenance facility, often at an airport or other remote location.

- Engineering Services (Non-Stock sales) — specialized technical support and expertise provided by MRO organizations or third-party providers for an aircraft MRO project.

- Power by the Hour — a maintenance program where an aircraft operator pays a fixed hourly rate to a service provider for the maintenance and repair of specific components or systems on their aircraft. This hourly rate covers both scheduled and unscheduled maintenance, including parts, labor, and other related costs. Essentially, it’s a way for operators to manage maintenance costs by converting them into a predictable, per-flight-hour expense.

How does Impresa MRO help reduce TAT and improve compliance?

Impresa MRO reduces turnaround time and strengthens compliance by digitally transforming aviation maintenance. Our platform orchestrates people, parts, tools, files, and data into one synchronized system—eliminating bottlenecks with real-time scheduling, automated compliance checks, tool tracking, and digital task sequencing.

Unlike legacy ERP add-ons or siloed tools, Impresa is purpose-built for MRO. We deliver true end-to-end visibility and audit-ready records, helping providers cut delays, streamline operations, and accelerate aircraft return-to-service while ensuring global regulatory alignment.

What is the total cost of ownership?

Impresa uses a simple subscription pricing model—no large upfront license fees, hidden maintenance costs, or heavy IT overhead. We designed it to fit the tight margins of MRO providers: on average, it works out to about the cost of a cup of coffee per user per day. This keeps your total cost of ownership predictable and affordable while giving you enterprise-level capabilities

Does Impresa support predictive and prescriptive maintenance?

Yes. Our open API integrates with IoT, AI platforms, and predictive analytics tools. We’re actively working with partners to leverage Impresa data for predictive and prescriptive use cases.

How does Impresa integrate with existing systems?

Impresa connects to ERP, PLM, MES, and OEM systems via open APIs to automate work and eliminate data silos. Benefits include:

- High-performance data flows

- Automation of manual processes

- Greater productivity

- Fewer errors & better accuracy

- Higher customer satisfaction

Aviation Maintenance Without Compromise

Impresa removes the tradeoffs between speed, compliance, and cost. With one connected platform, aviation providers eliminate inefficiencies, ensure regulatory readiness, and unlock new performance gains. Designed for today and ready for tomorrow, Impresa MRO is the partner of choice for organizations ready to modernize maintenance.

Impresa Corp.

30497 Canwood Street,

Suite 104

Agoura Hills,

CA 91301

SALES / TECHNICAL SUPPORT

1 (818) 874-9227 (USA Only)